ERP Software for Rice Mill

Streamline your Rice Milling operations - optimize , reduce costs, enhance profitability

From Unorganized Chaos to Complete Command: The ERP That Protects Every Kilo and Every Rupee in Your Mill

Rice Mill Samadhan ERP offers a robust platform that optimizes every aspect of your rice milling operations. From managing daily paddy prices to ensuring seamless integration of sales orders with dispatch and production processes, our system is built for efficiency and accuracy. Key features include automated price generation for ancillary items, effective control over contract labor tasks, and comprehensive dispatch management.

The Reality of Running a Rice Mill Today, you know the market better than anyone. Your instincts on paddy quality are sharp. But here’s what keeps you awake at night:

Paddy prices fluctuate daily, and your team is still updating rates on paper. By the time purchases are recorded, you’ve already overpaid on multiple consignments.

Your yield numbers don’t add up. 100 quintals of paddy should give predictable output—but conversion ratios never match reality. Where’s the leakage? Process inefficiency or pilferage? You simply don’t know.

Quality parameters mean nothing at the Kanta. Moisture is high, Pillai percentage is off—but purchase prices remain unchanged. You’re paying Grade-A rates for Grade-C paddy because nothing links QC results to pricing.

Labor billing is a black hole. Contractors invoice for tasks you can’t verify. You pay for 50 laborers when only 35 showed up.

Your plants don’t talk to each other. Sales, production, and dispatch operate in silos. You’re left piecing together truth from WhatsApp messages.

This isn’t just frustration. This is profit walking out of your gate daily. Samadhan Rice Mill ERP is an industry-specific solution designed for the complexities of Indian rice milling, from gate entry to dispatch, from single-plant operations to multi-location conglomerates.

Built on Microsoft Dynamics Business Central, Samadhan delivers:

- Enterprise-grade security protecting your operational data

- 99.9% uptime reliability your mill doesn’t stop for software crashes

- Role-tailored dashboards showing exactly what each user needs

- Seamless scalability from one plant to ten

You’ve worked too hard to trust operations to unverified local software. Samadhan gives you Fortune 500 reliability, configured for your rice mill.

Solving Your Biggest Profit Leaks:

Procurement Volatility → Daily Price Entry & Broker Masters- Enter the Base Paddy Daily Price once—the system automatically generates rates for bran, husk, and broken rice using pre-configured growth rates. Broker Masters maintain complete commission structures and payment terms. When mandi rates shift, you respond with precision.

Quality Blind Spots → Automated Quality-Based Pricing- Quality parameters, moisture, Pillai content, mix quality, are entered at the Quality Department, and the system automatically modifies Purchase Orders based on test results. High moisture? Price adjusts downward. Excessive broken percentage? The rate reflects it.

Labor Billing Fraud → Contract Labor Task Masters- The system creates verified records of tasks assigned, labor deployed, and state-wise wage calculations. Contractor invoices generate based purely on verified work done.

Multi-Plant Confusion → Unified Plant Management- Get consolidated inventory visibility, standardized processes across locations, inter-plant transfer tracking, and plant-wise profitability analysis, all from a single window.

Executive Blindness → Role-Tailored Dashboards- Real-time visibility into sales versus target, production output, pending dispatches, quality exceptions, and cash flow. Your floor supervisor sees operational data; your accountant sees financial entries. Everyone works in one system, but sees their relevant world.

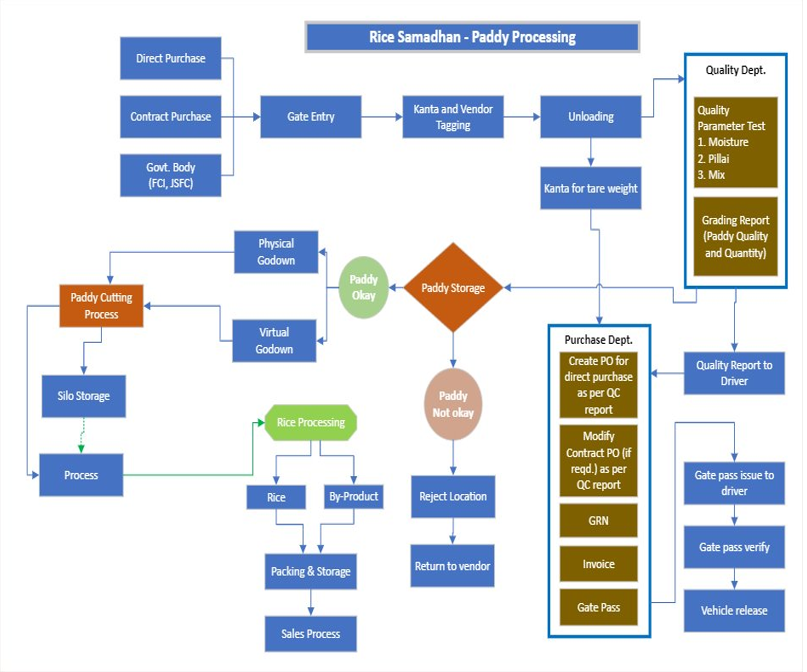

The Process Flow: Gate Entry to Vehicle Release

Gate Entry → Every vehicle logged and time-stamped

Kanta (First Weigh) → Gross weight captured digitally, integrated directly with system

Quality Department → Moisture, Pillai, mix tested; results flow automatically to pricing

PO Modification → System recalculates purchase rate based on QC results

Processing → Material moves with full traceability; yield calculations begin with verified weights

Final Weigh & Vehicle Release → Gate pass generated only when all checks complete

Effortless Price Management

Automatic updates of daily paddy prices and ancillary items.

Operational Efficiency

Seamless integration with dispatch and production reduces manual efforts and errors.

Quality Control

A robust QC module ensures superior control over the quality of paddy and ancillary items.

Every step recorded. Every weight verified. Every penny accounted for.

The rice milling industry is changing. Margins are tightening. The mills that will thrive aren't just those with the best paddy, they're those with the best systems. Samadhan Rice Mill ERP gives you structure to protect profits, visibility for faster decisions, and scalability to grow without losing control. Your Mill Deserves Better Than Guesswork

Why us?

We have the best rice mill specific solution, here’s why you should believe us?

Accurate Pricing

Our system ensures consistent, precise pricing for all paddy and ancillary items through automated calculations based on growth rates.

Enhanced Efficiency

Integration of sales orders with dispatch and production minimizes manual work and errors, streamlining operations.

Comprehensive Dispatch Management

Loading slip generation and optimized logistics ensure smooth transfers and workflow.

Superior Inventory Management

Efficient handling of packing, resizing, and reclassification of finished goods and by-products.

Quality Assurance

A dedicated QC module maintains high standards, ensuring only top-quality products reach the market.

+91 6287995736

Alternative way to get answer faster.

info@samadhanindia.com

We are always happy to help.